Aluminum Titanium Nitride (AlTiN) coating provide chip free hole edges and last at least 2 times longer than uncoated carbide tipped & 100 times longer than steel countersinks.

For use in handheld drill, drill press & CNC machine when used with CNC Spring Collet*. Carbide-tipped for long lasting results.

For use in handheld drill, drill press & CNC machine when used with CNC Spring Collet*. Carbide-tipped for long lasting results.

Used to countersink and counterbore holes for the heads of screws in woods, plastic and non-ferrous materials. The 2-flute integral design ensures uniform and concentric results each and every time. Available in a wide variety of sizes, complete with the High-Speed Steel (HSS) M2 fully ground drill bit.

AlTiN Coating Benefits:

Extra wear resistance

Allows for faster feed and speed rates

Cutting edge protected from wear

Better chip evacuation

Less heat build up

Superior cutting quality and extended tool life

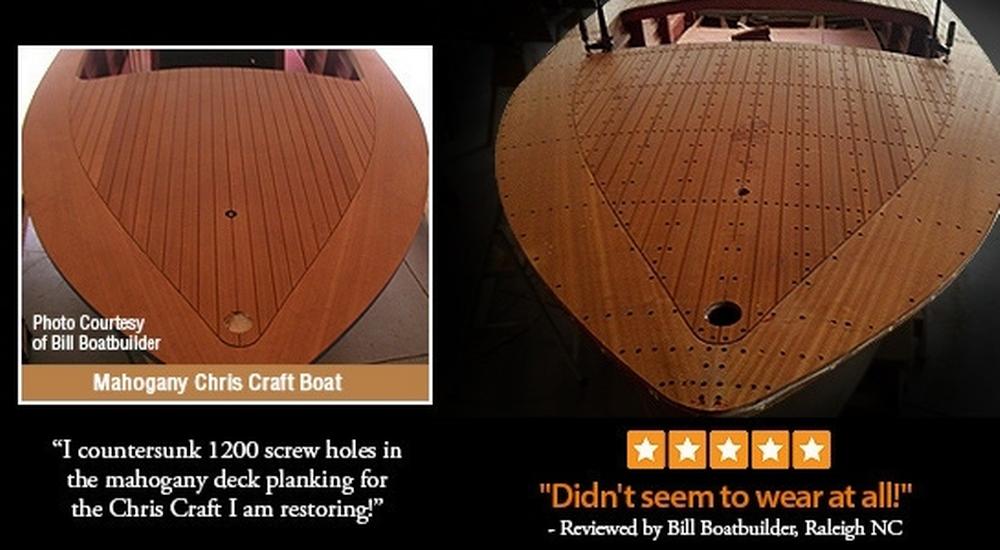

Excellent for Drilling:

Natural Woods

Man-Made Boards

MDF

Chipboard

Plywood

Aluminum/Non-Ferrous*

Aluminum Composite Materials (ACM)*

Composite Decking Materials

*WARNING!: For optimal results and extended tool life use lubricant or air cooling. Ensure the material is fixed and drill is stable while drilling.

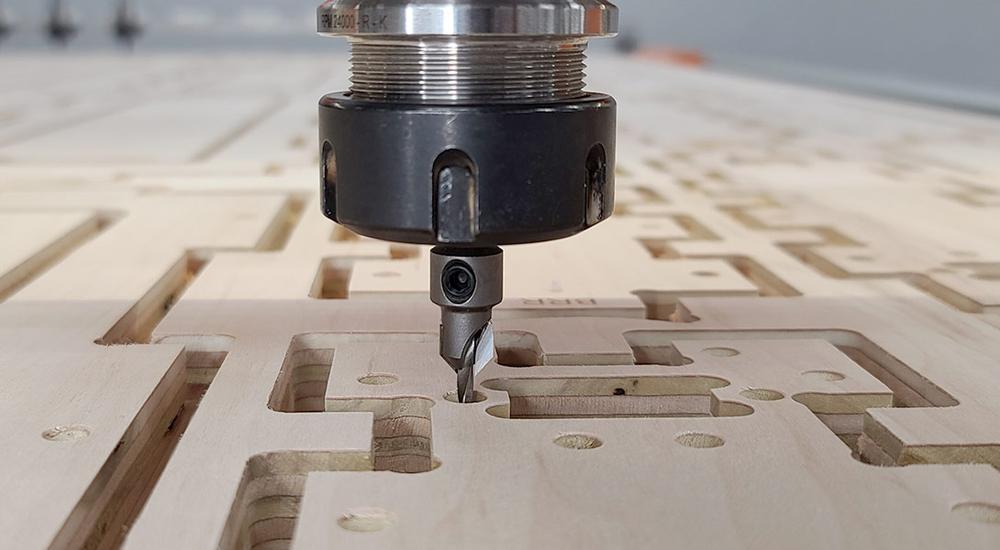

CNC Countersink

Drilling countersinks with these bits on the CNC machine is a great way to save time and have your pieces look great every time!

With the adjustable depth drill bit you can adjust them for whatever size material you’re working with. They are best used with a drilling toolpath, utilizing the peck drill option at 0.25” per pass with a 0.125” retract height.

For best results run at 3,000 RPM with a 30 Inches Per Minute (IPM) plunge rate. No feed rate needs to be set with these as they only move up and down with the Z axis, not side to side. If your software doesn’t allow a 0 feed rate, you can enter 1 IPM in the feed rate as a placeholder.

*For 5/16" dia. round shank use a 7-8mm Spring Collet. For 3/8" dia. round shank use 9-10mm Spring Collet.